Decoding Common Noises From Your Sewing Machine

If you’re new to sewing, you may be stressed decoding common noises from your sewing machine. As a beginner, it can be quite unsettling to hear clicks, knocks, and other strange sounds.

Fear not, though – understanding these noises can help you maintain your machine and prolong its life, ensuring a smoother sewing experience.

Before you panic, it’s important to remember that sewing machines naturally produce some noise during operation. Gaining a solid grasp of the normal sounds your machine makes will help you differentiate them from any unusual sounds that may need more attention.

In this article, we’ll decode some common sewing machine noises and guide you through the appropriate actions to address them, while also offering preventative tips to keep your machine running smoothly for years to come.

Table of Contents

- 1 Understanding Normal Sewing Machine Noises

- 2 Identifying Abnormal Sewing Machine Noises

- 3 Appropriate Actions to Take When Unusual Noises are Heard

- 4 Prevention Tips to Avoid Sewing Machine Noise Problems

- 5 Decoding Common Noises From Your Sewing Machine TakeAway

- 6 History of the Sewing Machine

- 7 Frequently Asked Questions

- 7.1 Why is my sewing machine so loud?

- 7.2 How can I fix the clunking noise in my sewing machine?

- 7.3 Why is my sewing machine squeaking?

- 7.4 What causes a grinding noise in a Singer sewing machine?

- 7.5 How to resolve a clicking noise in my sewing machine?

- 7.6 Why does my sewing machine sound like the needle is hitting something?

- 7.7 What should I do if my sewing machine is making a high pitched noise?

Key Takeaways Decoding Common Noises From Your Sewing Machine

- Noises from sewing machines can be understood and addressed

- Learning about normal machine sounds will help identify unusual ones

- Proper maintenance and prevention can extend your sewing machine’s life

| Section | Summary |

|---|---|

| Understanding Normal Sewing Machine Noises | Normal sewing machine sounds include the hum of the motor, the click of the needle, and the whirr of the bobbin winding. Regular maintenance, using high-quality materials, and replacing needles regularly can prevent abnormal noises. |

| Identifying Abnormal Sewing Machine Noises | Grinding or crunching sound often results from a lack of lubrication. Popping or banging noises could be caused by a bent or damaged needle, a tangled thread, or loose parts. High-pitched squealing or buzzing sounds might indicate friction caused by dull needles, incorrect thread tension, or dust buildup. |

| Appropriate Actions to Take When Unusual Noises are Heard | Simple DIY fixes for common issues include cleaning, oiling, changing needles, and checking tension setting. If these don’t work, consult a professional sewing machine technician. |

| Prevention Tips to Avoid Sewing Machine Noise Problems | Regular cleaning and lubrication, using the right needle and thread, and proper storage can help prevent noise problems and prolong the machine’s lifespan. |

| Frequently Asked Questions | Covered common questions about sewing machine noises, including causes and potential solutions for loud noises, clunking noises, grinding noises, clicking noises, hitting noises, and high pitched noises. |

Understanding Normal Sewing Machine Noises

Congratulations on your first sewing machine! As you begin to explore the world of sewing, you may notice that your sewing machine makes a variety of sounds while operating.

Don’t worry, this is normal. In fact, understanding these noises is essential for a smooth sewing experience. This section is here to help you identify, understand, and decode common noises from your sewing machine.

A sewing machine, when functioning properly, makes a few signature noises. The hum of the motor, the click of the needle, and the whirr of the bobbin winding are all part of a normal sewing process.

These sounds may alter slightly depending on the stitching technique you’re using, the type of fabric you’re working with, and the speed at which you’re sewing.

Now, let’s break down some of the common noises you might encounter and their meanings:

-

The hum of the motor: This is the most constant noise you’ll hear while your sewing machine is running. It’s simply the sound of the motor powering your machine.

-

The click of the needle: As the needle moves up and down, it produces a rhythmic clicking noise. This is a normal part of the sewing process, and it indicates that your needle is functioning correctly.

-

The whirr of the bobbin winding: When you’re winding the bobbin, your sewing machine might produce a whirring sound. This noise is also normal and indicates that the bobbin is winding evenly.

To ensure that these normal noises don’t turn into something more worrying, it’s crucial to perform regular maintenance on your sewing machine. This includes cleaning the bobbin area and removing lint buildup, oiling the machine, and checking the needle plate for damages.

Proper lubrication of the feed dogs and tension mechanism can also improve your sewing experience.

Another tip to maintain your sewing machine in good condition is to use high-quality thread and fabric suitable for the type of needle you’re using. Also, remember to replace your needles regularly, as a dull or damaged needle can affect the sewing performance and cause unnecessary noise.

In conclusion, it’s essential to familiarize yourself with the normal sounds of your sewing machine. If you hear any unusual noises that don’t fit the descriptions mentioned above, check for potential issues and perform the necessary maintenance.

As you continue your sewing journey, you’ll become more comfortable with your machine’s unique sounds and can confidently enjoy your creative projects!

Identifying Abnormal Sewing Machine Noises

Don’t worry if your sewing machine starts making strange noises – it’s a common issue faced by beginners. It’s essential to determine whether a sound is normal or indicative of a problem.

Familiarizing yourself with your sewing machine is a crucial first step to feel more confident and ensure a satisfying sewing experience.

Some noises such as motor humming, needle clicking, and bobbin winding are non-problematic and part of the regular operation of your sewing machine. However, other noises may require your attention and possibly some troubleshooting.

Grinding or crunching sound often results from a lack of lubrication or mechanisms rubbing against each other. Ensure that the gears, hook, and needle bar of your sewing machine are properly lubricated according to the manufacturer’s instructions.

Popping or banging noises could be caused by a bent or damaged needle, a tangled thread, or loose parts. Keep a close eye on the area where the needle meets the fabric and ensure it is straight and undamaged.

Additionally, check for any tangled threads or loose screws in your sewing machine.

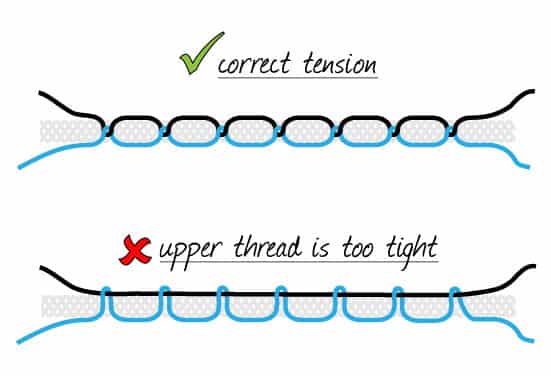

High-pitched squealing or buzzing sounds might be a sign of friction caused by dull needles, incorrect thread tension, or dust buildup. Always use the right sewing needle for your project and change it regularly.

Make sure your upper thread tension is adequate, and maintain your machine by regularly cleaning it and removing any dust.

Knocking or clunking noises can occur when the bobbin winder is engaged, or if your rotary hook isn’t working correctly. Inspect the bobbin winder and ensure it is disengaged before sewing.

Clean the bobbin area of your machine and remove any debris if necessary.

Lastly, if you still have concerns and can’t figure out the cause of the noise, inspect your sewing machine thoroughly for any loose components or faulty parts. In some cases, you might need to seek professional assistance to resolve the issue.

Remember, it’s normal for sewing machines to make some noise during operation. By carefully listening and identifying abnormal noises, you can troubleshoot minor issues and ensure your sewing machine continues to run smoothly.

Stay calm and investigate logically, and you’ll soon become an expert in maintaining your sewing machine. Happy sewing!

Appropriate Actions to Take When Unusual Noises are Heard

First of all, don’t panic! Hearing unusual noises from your sewing machine can be a bit startling, especially for beginner sewers. However, in most cases, these noises are just signs that your machine needs some attention or maintenance.

Let’s go through some appropriate actions you can take when you hear these noises.

Decoding Common Noises From Your Sewing Machine: Simple DIY Fixes for Common Issues

Often, the cause of the noise can be resolved with some simple do-it-yourself fixes. Here are a few suggestions:

- Cleaning: Make sure you thoroughly clean your machine, especially the bobbin area, as dust and thread remnants might cause unwanted noises. Remove the throat plate and use a small brush to gently clean the area.

- Oiling: Consult your sewing machine manual to understand the oiling process. Properly oiling your machine can help with noisy operation and reduce friction between moving parts.

- Changing needles: A bent or loose needle can cause strange noises. Always make sure the needle is correctly inserted and secured. Replace it if necessary.

- Tension setting: Double-check the tension setting on your machine. An improper tension setting can create noises and affect the quality of your sewing.

Decoding Common Noises From Your Sewing Machine: When to Consult a Professional Sewing Machine Technician

While many common issues can be fixed at home, there are situations where consulting a professional sewing machine technician is necessary:

- Engaged bobbin winder: If your machine is making a grinding noise, check if the bobbin winder is engaged. If it’s not the cause, consider seeking professional help.

- Broken parts or hook timing issue: If you suspect broken parts or a hook timing problem, don’t attempt to fix it yourself. Instead, consult a professional to ensure your machine remains in good working condition.

- Specialized materials: If you’re working with materials like leather or heavy fabrics, you might need to use a specific type of needle, thread, or gauge. Check your sewing machine manual for recommendations and consult a professional if needed.

Remember, it’s always better to address any unusual noises right away to prevent further damage to your sewing machine. With proper care and regular maintenance, you can keep your machine running smoothly and efficiently for years to come.

Prevention Tips to Avoid Sewing Machine Noise Problems

Don’t worry! Decoding common noises from your sewing machine can seem scary at first, but they are often easy to resolve. Let’s go through some simple prevention tips to minimize noise problems and keep your machine running smoothly without causing you any panic.

Routine Maintenance: A key to keeping your sewing machine quiet is to perform regular maintenance. This means you should frequently clean, lubricate, and inspect your machine.

By staying on top of these tasks, you can avoid build-ups of dust, thread, and lint that may cause unsettling noises and affect the machine’s performance.

Regular Cleaning: Make it a habit to clean your sewing machine after every project. Remove any thread or fabric debris from the needle, bobbin, and feed dogs. Brush out lint from the bobbin case to prevent any knocking noise caused by blockage. Maintaining a clean working environment will not only keep your machine noise-free but also extend its lifespan.

Proper Lubrication: Oiling your sewing machine is an essential part of maintenance. Apply a few drops of oil to the moving parts, as specified in your sewing machine manual, to prevent friction- related issues and noises. Be cautious about over-oiling, as it can lead to more problems instead of resolving them.

Right Needle and Thread: Using the appropriate needle and thread for your project can prevent noise issues. Replace your needles every 16 hours of stitching time to avoid breakage, bending, or damage. Choose the proper thread thickness and fabric type, as these factors also contribute to the machine’s noise level.

Storage: When not in use, store your sewing machine in a clean, dry place, away from dust and potential damage. This will help maintain its condition and prolong its life, allowing you to enjoy your sewing projects without any bothersome noises.

Remember, you haven’t broken your first sewing machine! By following these prevention tips, you’ll be able to solve and avert possible noise problems, ensuring a smooth and enjoyable sewing experience. Happy sewing!

Decoding Common Noises From Your Sewing Machine TakeAway

Learning to understand and decode the common noises from your sewing machine is essential for early detection of potential problems. By being attentive to unusual sounds, you can prevent damage to your machine and ensure a smooth sewing experience.

In this article, we have discussed various causes of noises and their possible solutions.

It’s natural for a beginner to feel worried when they hear strange noises coming from their first sewing machine. However, remember that most of these sounds can be easily identified and resolved. Stay calm and follow the logical steps we’ve provided to figure out the cause of the noise.

For example, a squeaking noise may indicate a lack of lubrication in the machine’s inner mechanisms. Similarly, a knocking sound might be caused by a damaged, bent, or dull needle.

Paying attention to these signs can help you address the issues on time and avoid further damage to your sewing machine.

As a beginner, it’s crucial to remember that timely maintenance and care can significantly prolong your sewing machine’s life. Don’t be afraid of the noises; instead, use them as cues to take appropriate action.

Following the solutions mentioned in the article will not only help you resolve the issues but also build your confidence as a sewer.

Remember, early detection and troubleshooting are key to preventing significant damage and maintaining your sewing machine’s performance. Keep practicing, stay observant, and don’t let the fear of noises hold you back. Your friendly sewing machine is your partner in creativity, and together, you can create wonders.

History of the Sewing Machine

In the world of textile manufacturing, a sewing machine is a ubiquitous tool that revolutionized the garment industry. Developed in the early 19th century, this mechanical device is designed to stitch fabrics together with precision and efficiency.

Powered by either electricity or foot pedals, a sewing machine operates by guiding a threaded needle through layers of fabric, creating strong and durable seams. The distinct sound of a sewing machine is often described as a rhythmic whirring or humming, a result of the motor and gears working harmoniously to propel the needle up and down, piercing through the fabric.

This familiar sound has become synonymous with the art of sewing and is a comforting auditory reminder for those who are skilled in the craft.

Frequently Asked Questions

Why is my sewing machine so loud?

Why is my sewing machine so loud? Check for improper installation, accumulated dust, or using the wrong type of fabric. Don’t worry – most of these issues can be easily fixed by checking the machine’s setup and giving it a thorough cleaning.

How can I fix the clunking noise in my sewing machine?

How can I fix the clunking noise in my sewing machine? A clunking noise might be caused by a damaged or bent needle. To fix this issue, inspect your needle and replace it if it looks damaged, bent, or dull. Using the correct needle type and size for your fabric and project is also important to prevent future problems.

Why is my sewing machine squeaking?

Debris is the most common reason for hearing squeaking noises from your sewing machine. Dust is easy to remove by taking a small air jet blower to the feed dogs to remove threads or small pieces of fabric.

What causes a grinding noise in a Singer sewing machine?

What causes a grinding noise in a Singer sewing machine? Grinding noises might be due to worn out gears or parts being out of alignment. To resolve this, give your sewing machine a thorough cleaning and lubrication, making sure to remove any dust or debris from the gears. If the problem persists, consider consulting a professional technician.

How to resolve a clicking noise in my sewing machine?

How to resolve a clicking noise in my sewing machine? Noise can be caused by a variety of issues, including thread tension, damaged feed dogs, or the needle hitting something within the machine.

First, check the tension settings and make sure they’re appropriate for your fabric. If the problem persists, inspect the feed dogs and needle for any damage. Give your machine a proper cleaning, making sure to remove any lint or debris that might be causing the issue.

Why does my sewing machine sound like the needle is hitting something?

Why does my sewing machine sound like the needle is hitting something? A damaged or bent needle, or an issue with the bobbin case will cause a hitting noise. Check the needle for any visible damage, and replace it if necessary. Also, ensure that the bobbin case is properly seated and free from debris or lint.

What should I do if my sewing machine is making a high pitched noise?

What should I do if my sewing machine is making a high pitched noise? High pitched noises can result from motor or wiring issues. First, try unplugging the machine and plugging it back in – this can sometimes solve minor electrical problems.

If the noise persists, consult your sewing machine’s user manual or contact a professional technician for help. Remember, it’s always better to address these issues early on, so don’t hesitate to seek assistance.